Like most quality tools, the Flowchart transcends the quality management barriers and is one of those tools that can be used in multiple fields. We can see frequent applications in software development, project management, education, sales, business process mapping, and so on. And chances are, you’ve most likely seen one of these around at some point in your life – it’s one of those things we use but don’t necessarily know what it’s called.

So, what is this tool more precisely? The Flowchart is a visual representation of a process, which highlights its steps in sequential order. It is a tool commonly used for process analysis and it is considered to be one of the seven basic quality management tools.

To dumb it down even more, think of it like this: each process, whether it’s manufacturing tea kettles, sewing dresses or manufacturing computer parts has a set of separate steps that need to be followed to achieve the results. For our sewing of dresses process example, it could turn out disastrous to cut the material without measuring first. In this case, the end product that we are trying to produce would be ruined or would require rework – and with that, the costs of producing that product would go up. In some cases, not following the appropriate steps could be life-threatening.

So, if we know that each process has a set of steps that need to be followed in a certain order for the result to be good then wouldn’t a tool that allowed us to “draw” this process be useful? But if I already know what steps need to be taken, then why use a tool? You might ask yourself. Because depending on the process that we work on, even if it’s something we’ve done a million times before, we might forget a step, or a small aspect – whether due to the limited time you have available for doing it, being distracted, being tired and so on. Or it might be one of those things that you only rarely do and need a short memory refresher on how it’s done (Think of that one food you cook just once or twice a year – don’t you have to check the recipe to make sure you know all the ingredients and the order everything is cooked in). Not to mention how easy the Flowchart can make the life of new employees and can empower them to learn faster without having to depend on others.

The flowchart is also useful for documenting your process. And not to mention how useful the flowchart could be if you wanted to better understand a process to improve it, or to figure out what causes/issues are causing problems or bottlenecks.

Ok, so now that I’ve hopefully convinced you to give this tool a try, let’s see how it’s used. First and foremost, you will need to understand the symbols used for drawing a flowchart so while there are some minor variations on these, I prefer to stick to the symbols used by the American Society for Quality (ASQ). Therefore, according to this, mostly commonly:

- Rectangles are used for representing process steps

- The Diamond shape is used whenever a decision based on a question needs to be made

- A semicircle is used to represent delays or wait times

- Ovals, or squares with rounded corners are used for start and end points.

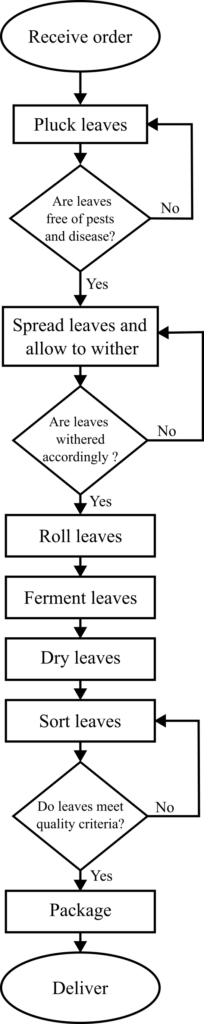

So let’s take a look at how a flowchart could be used to represent the production process for our fictional tea factory. We know that after an order is received the factory workers have to pluck the top two leaves and buds and check to make sure that the leaves don’t have pests or diseases. Once the ok leaves have been selected, they are then spread into thin layers on withering racks to allow the leaves to wither and lose 30 to 40 % of moisture content. After an inspection for moisture content takes place, the leaves are then rolled with the help of rolling machines which have to be set correctly to ensure that the cell walls of the leaves are broken and the enzymes are released. After this, the fermentation process begins, where it is important to maintain proper temperature and humidity levels and check the leaf color changes until the desired oxidation level is achieved. The leaves are then dried until the moisture content is reduced to 3-5%, and once that is done, the leaves are sorted according to size and quality. A quality control check verifies that all leaves meet the company’s quality standards, after which the leaves are packaged and delivered thus ending the production process. Pretty simple and logical right? But what happens when you’re a new employee and you don’t have the written production process and have to remember each step? Or what happens when you want to bring improvements to a process but it’s hard to keep track of each step, each decision gate, quality checkpoint, and so on?

So, now that we know how the production process works, we can sketch the flowchart.

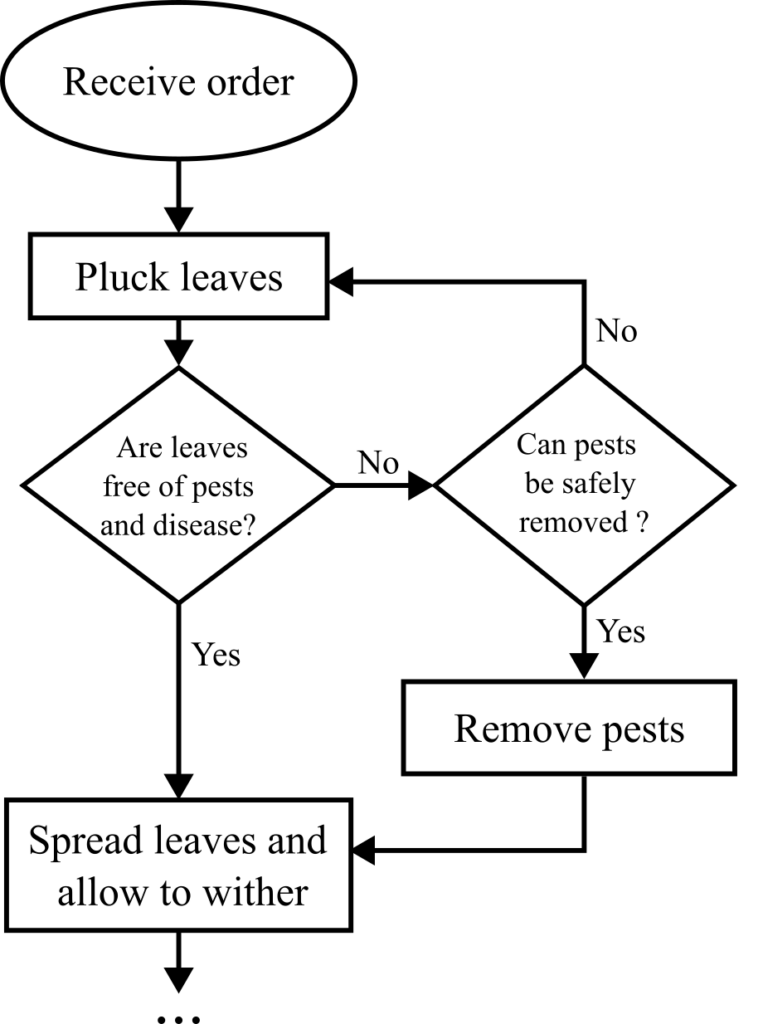

Now this was a very basic and simple example of a flowchart, it can be a lot more complex than this. And of course, even this chart could’ve been more complex if the production process was more complex. Even so, by looking at the flowchart, we could find two possible directions of improvement. For instance, after the leaves are checked to make sure that they are free from pests and diseases if nonconforming leaves are found (meaning these leaves have either pest, disease signs, or a combination), the production process assumes that new leaves should be plucked, leaving these most likely to be scrapped. But depending on the quality policy inside the factory we could decide that if the pests can be safely removed and there’s no damage done to the tea leaf, the workers can choose to remove the pest and send the leaf to the next process step rather than pick up new leaves. This would imply another decision point stemming from the answer no to the first question of the flowchart. I’ve added below just that segment to see how that area of the flowchart would change in this case.

A similar improvement can be made in the decision process regarding the quality criteria of the leaves. The factory can choose to scrap those leaves that are not by their standards or sell those leaves at a smaller price or to another factory and so on.

Another useful thing to know about the flowchart is that there are templates out there (there are a couple of free ones as well) that you can use if you find it helpful. I prefer to keep things very basic and draw from scratch but if using a template works for you, you should not shy away from it.

Of course, as always, it is important to remember that this tool is meant to help you and be adapted to your particulars so feel free to adjust templates, complicate or simplify the flowchart until it fits your needs.

Leave a Reply